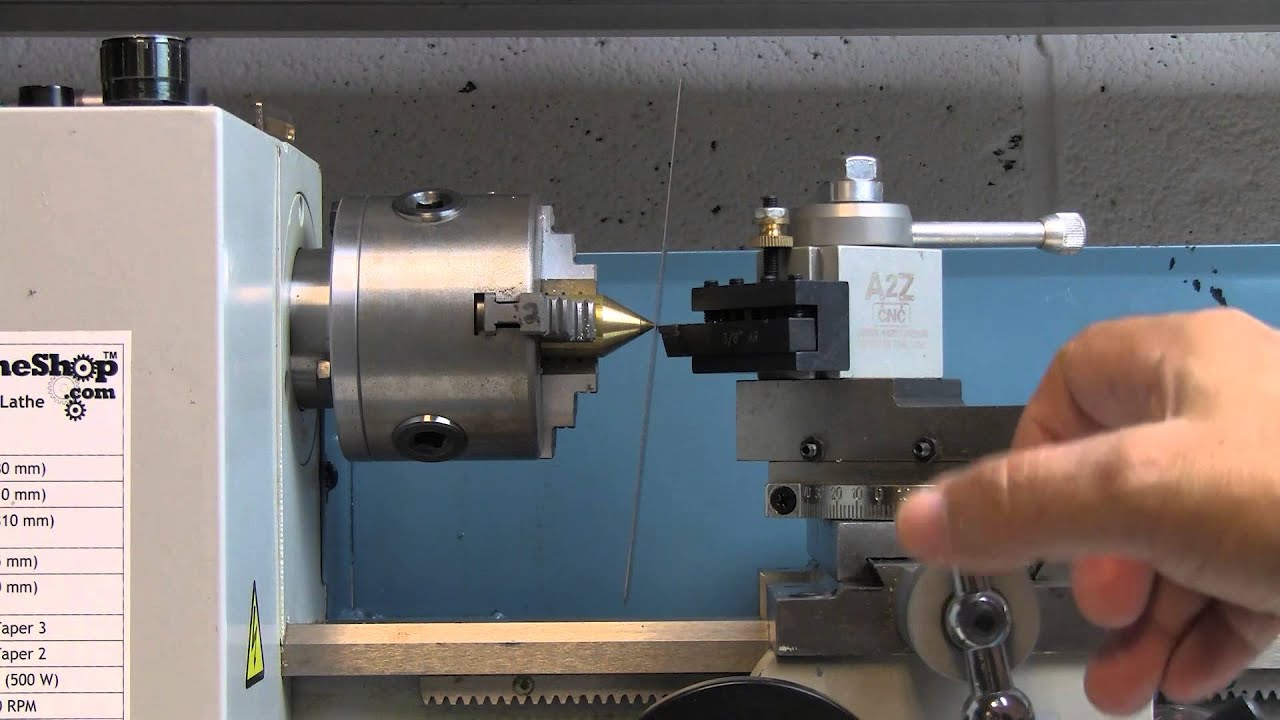

It is important that the correct lathe chuck is selected to hold a workpiece, as a workpiece clamped too loosely or not correctly could be a health and safety risk, or cause the job to be scrapped.Īt the other end of the workpiece, or the ‘tail end’ of a lathe, is the tailstock. The chuck will then spin at a given speed (either computer programmed in CNC lathes or manually set on a conventional lathe), in turn rotating the workpiece. scroll chuck, power chuck, independent chuck) feature a certain number of jaws, which will be used to clamp a workpiece securely. These components include a spindle and tailstock, which are both used to hold a workpiece in place during operation.Īlthough technically a lathe can have multiple spindles (another commonly being the tailstock or sub spindle), usually when describing a lathe spindle this refers to the ‘main’ spindle where a lathe chuck will sit. It essentially acts as a track whereby other lathe components sit and move along. Most lathes are built on a machine bed, which runs horizontally across the whole length of a lathe. Lathes can vary from very basic (for small-scale hobbyist uses like shaping pottery or woodworking) to large-scale CNC lathe units capable of lumping off massive quantities of metal. Lathes can perform a variety of applications including turning, boring, parting off, knurling, threading, corner rounding, grooving, forming, drilling and face grooving.

This differs from a milling machine as it is the workpiece that rotates, whilst the machine tool used to shape, cut or machine the workpiece remains stationary. What is a lathe and what are its main features?Ī lathe is a piece of engineering equipment commonly used to machine workpieces by rotating the workpiece around a given axis.

0 kommentar(er)

0 kommentar(er)